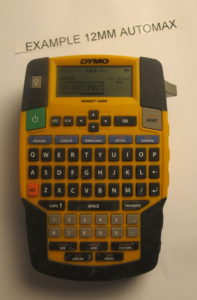

To breathe some life into my dead weblog again, a long put-off review of a useful piece of hardware I own, the Dymo Rhino 4200 thermal transfer label printer.

Introduction

If you, like me, involve yourself with various DIY hobbys (like 3D printing, photography, and various electronics, mechanics) you will end up with lots of containers with certain parts and/or materials in them. Labels that are easy to read and durable are in my opinion an essential tool for the home DIY hobbyist. They show what is (or should be) in a container. They will also make you think about your system of categorizing materials.

As I mentioned, printed labels are durable. That is, if they are of the gold standard of label printing, thermal transfer printing. Of course, this is a hyperbole, you’re always better off with that old school embossing printer or the cheapest Dymo direct thermal than nothing at all.

But for quality permanent labels, thermal transfer is in my opinion the best.

BTW: TT printers are undeniably not a jack of all trades. For example, for mass printing shipping/price labels this technology is overengineered and much too expensive. In this domain direct thermal printing dominates.

Outline of thermal transfer printing

The principle behind TT printing is simple. Either stock label ribbon or a tear-off strip of labels is pushed, together with transfer foil, against a printing head. This head is a bit like the printer heads of old matrix printers, it contains a vertical row of pins. But instead of hammering against an ink ribbon they are individually heated. At that point, the “ink” on the ribbon will melt and fuse with the label material. When all the required pixels in a row have done their job, the label material and spent foil is moved on. Printing resumes until the end of the label. Depending on the type of printer labels can be automatically cut from stock ribbon, but this is a feature usually seen on expensive, high performance printers.

Regardless of type/make, TT printers of any brand offer a wide variety of label material (paper, nylon, polyester, autolaminating, shrink wrap tube etc.) and many label/foil color combinations. You are often not bound to buy brand name label material, various companies provide off-brand options which often work just as well

This article reviews a printer which works with cartridges, but know that larger industrial printers often run on separate rolls of label stock and foil.

Overview of the printer

The Dymo RHINO 4200 is a basic thermal transfer label printer. It works with cartridges with ribbon lengths of max 10m and widths 6, 9, 12, and 19mm. The printer is powered by either 6 AA cells (9v total nominal voltage) , 9VDC from a mains adapter, or an internally chargeable 7,2V Li-ion battery. The unit has a large, easily readable display which can be illuminated if needed.

It’s going price seems to be around 70-100 US dollars or euros, which I consider affordable.

Construction “quality”

This printer is marketed as being of “industrial” construction, which it clearly is not. The housing features rubberized corners to supposedly protect it from falls but once you see the inside construction one can’t help laughing. Cheap, brittle ABS that has been intentionally dimensioned a bit too thin. In fact, I had to repair my printer myself after it went completely dead after a fall on a laminate apartment floor. Luckily the unit is very easy to open and the fault was quickly located, a crack in a PCB trace carrying power from the batteries. Removed the varnish coating of the trace, resoldered it, verified functionality and overapplied hot glue just to be sure.

General usage

This printer will only detect a cartridge change, not what size it is. You can make the printer think it has more print area available by setting a higher cartridge size. Sometimes this makes it possible to print larger characters on cartridges smaller than 19mm 🙂

For easy entering of letters the printer has a QWERTY layout. You don’t want anything else if you are a label addict like me, believe me. Special characters are accessible by long-pressing a letter on the keyboard or through the LIBRARY key. As far as I see there is no support for Cyrillic and Greek at all or you need to buy a different version. A useful function is the ability to store favorite symbols that are too deeply buried into the annoying menu system. An annoying quirk is that symbols like those for acids, HV, biohazard are messed up if you apply bold formatting.

The printer provides basic word processor conventions like bold, italic, underlined, orientation, mirroring etc. but only at a per-label level. There is no WYSIWYG functionality, it shows the text and various static LCD elements that show text style. You do however, get to define “sub”labels that can have different text styles.

There is also support for various labels useful in industrial/IT environments. You can print out text with a combined incrementing serial number, cable tags in both “flag” and “wrap” style. Want to put a 128/39 type barcode on something, also no problem.

For anyone who wants to know more, here’s a link to the manual.

Conclusion

Affordable Thermal Transfer printing is made possible with this unit. I have used it a lot without much issues. Regardless of it’s ridiculous pretension to be some kind of rugged industrial device I consider it good value for money. It just works and you can save some serious money buying non-Dymo branded cartridges, which will usually work just as well.

Finally, some overal pros and cons to consider:

- Good value for money

- Large variety of label material available

- Generally easy to use

- Not high resolution but consistent crisp printing quality

Some less desirable properties of this printer:

- Weak construction which will not survive in industrial environments

- Eats AA cells like crazy

- The optional Li-ion battery is expensive AF

- Not that quick

- You are limited in applying formatting on a per-label base

- No PC interface

As you can see this printer has some flaws but it works and can generally be had far under €/$100 and in a home environment it will provide many hours and meters of obsessive-compulsive labeling.